Arduino Projects A Joystick Controlled Industrial Automation

In an era where technology permeates every facet of human endeavor, the amalgamation of automation and user interactivity has become a focal point for innovation. Enter the realm of Arduino projects, where creativity melds seamlessly with engineering expertise. Among the myriad of possibilities, the joystick-controlled industrial automation system stands out, offering not just functionality but a profound and deeper meaning in its operation and application. This project epitomizes the convergence of user intuition and mechanical precision, thus redefining the interactions between man and machine.

Arduino, an open-source electronics platform, has captivated the imagination of hobbyists and professionals alike since its inception. Its versatility allows individuals to manipulate components and integrate various technologies effortlessly. The joystick-controlled industrial automation system serves as a quintessential example of this capability, demonstrating how simple controls can lead to sophisticated outcomes in industrial settings.

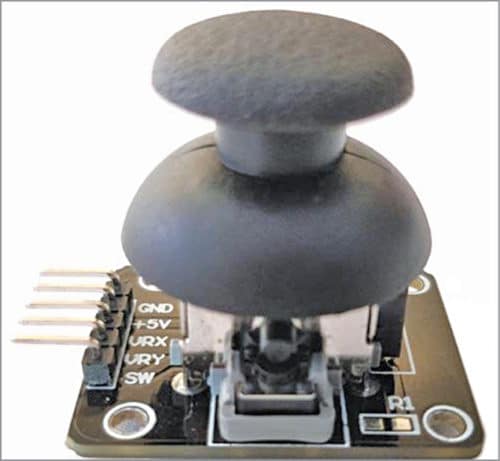

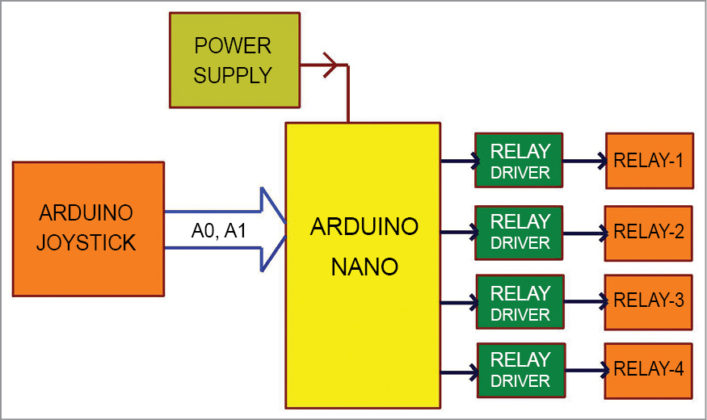

The foundational aspects of constructing a joystick-controlled system revolve around a few critical components: the Arduino microcontroller, a joystick module, and the actuators or motors that will be controlled. The joystick serves as the input device, translating the user’s motions into commands that the Arduino processes. By leveraging the analog output of the joystick, one can achieve nuanced control over the connected machinery, creating a direct line of communication between the operator and the system’s operational mechanisms.

Before delving deeper into the intricacies of the project, it’s essential to establish the basic hardware requirements. A standard Arduino board, such as the Arduino Uno, is typically the heart of the project. The joystick module, often comprised of two potentiometers and a push-button switch, provides two axes of movement and a means to execute additional commands. This enables a multi-faceted interaction – turning a simple command into a dynamic series of actions.

To implement this project effectively, one must also consider the additional components required for connecting the motors. Depending on the application’s complexity, various motor drivers can be integrated, ensuring that the Arduino can control DC motors, stepper motors, or servos with precision. This aspect highlights the inherent scalability of the system; it can be modified to accommodate different operational requirements, ranging from small-scale models to large industrial applications.

Upon establishing the necessary hardware, the next step involves the programming aspect. The Arduino Integrated Development Environment (IDE) enables users to write and upload sketches – small programs that dictate the functionality of the hardware. Open-source libraries can be utilized to facilitate communication between the joystick and the Arduino, simplifying the coding process. Most notably, the joyStick library can decode the analog signals emitted by the joystick, translating them into actionable commands.

As one embarks on the coding journey, it is crucial to acknowledge the significance of real-time control within industrial automation. The joystick’s responsiveness plays a pivotal role, and thus, employing suitable algorithms to ensure minimal latency is essential. A programmable loop within the sketch continuously reads the joystick’s position and transmits corresponding commands to the motors. This allows for immediate feedback, creating a harmonious interaction between input and output that is instrumental in achieving precise automation.

Moreover, implementing feedback systems—such as encoders for motor position tracking—enhances the project’s complexity and effectiveness. This feature allows the system not only to relay commands but also to adapt its operations based on real-time data, further refining the automation process. The duality of control and feedback represents a critical stride towards achieving a self-regulating system, a hallmark of advanced industrial automation.

The implications of creating a joystick-controlled industrial automation system extend far beyond mere technical accomplishment. This project echoes the changing dynamics of labor in industrial environments. In a landscape increasingly characterized by smart factories and the Internet of Things (IoT), it illustrates how human operators can maintain control over automated processes while still benefitting from the efficiencies that modern technology provides.

As industries embrace automation, the ability to directly interact with machinery via intuitive controls becomes invaluable. The joystick-controlled system represents a paradigm shift, empowering operators to engage actively rather than passively overseeing complex processes. This transition not only optimizes productivity but also enriches the user experience, nurturing a sentiment of ownership and responsibility towards the machinery being operated.

Additionally, the educational possibilities inherent in this project present a tantalizing opportunity for aspiring engineers and technologists. By engaging with a hands-on project involving Arduino and joystick controls, learners can cultivate critical skills that are highly sought after in today’s job market. This system serves not only as a technical exercise but also as a gateway to understanding the broader implications of automation in the industrial landscape.

In conclusion, the joystick-controlled industrial automation system encapsulates the essence of modern technology by marrying simplicity with sophistication. As the digital and physical realms continue to coalesce, this project serves as an excellent avenue for exploring the depths of user interaction within automated environments. The journey from conceptualization to implementation not only reinforces technical prowess but also engenders a deeper understanding of the evolving nature of work in an automated future. The path ahead is illuminated by infinite possibilities, where the only limitation resides in the imaginations of creators ready to push the boundaries of what is achievable.

If you are searching about Joystick-Controlled Industrial Automation System – Electro DSM you’ve came to the right web. We have 10 Pictures about Joystick-Controlled Industrial Automation System – Electro DSM like Funduino (Arduino Joystick Shield) Controlled Robot | Arduino | Maker Pro, Joystick-Controlled Industrial Automation System – Electro DSM and also Joystick-Controlled Industrial Automation System – Electro DSM. Here it is:

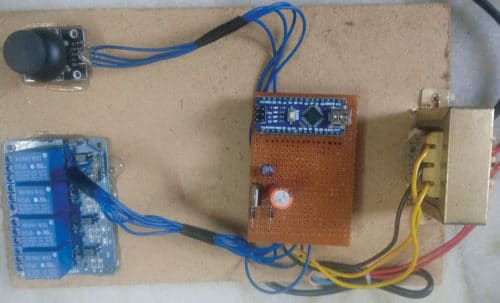

Joystick-Controlled Industrial Automation System – Electro DSM

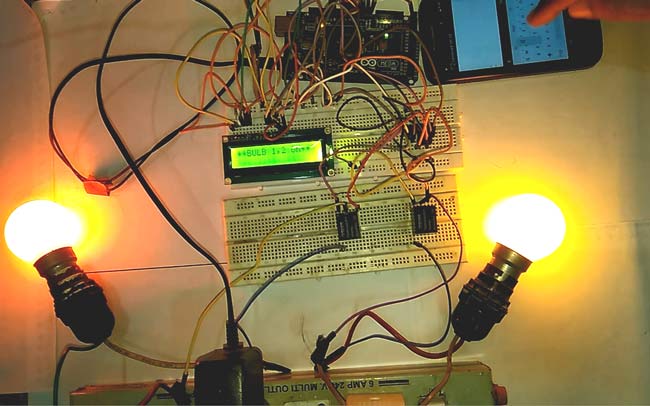

electrodsm.wordpress.com### Smart Phone Controlled Home Automation Project Using Arduino

electrodsm.wordpress.com### Smart Phone Controlled Home Automation Project Using Arduino

circuitdigest.comautomation arduino smart using controlled phone projects project ir gsm many can technologies essence today life make world our bluetooth

circuitdigest.comautomation arduino smart using controlled phone projects project ir gsm many can technologies essence today life make world our bluetooth

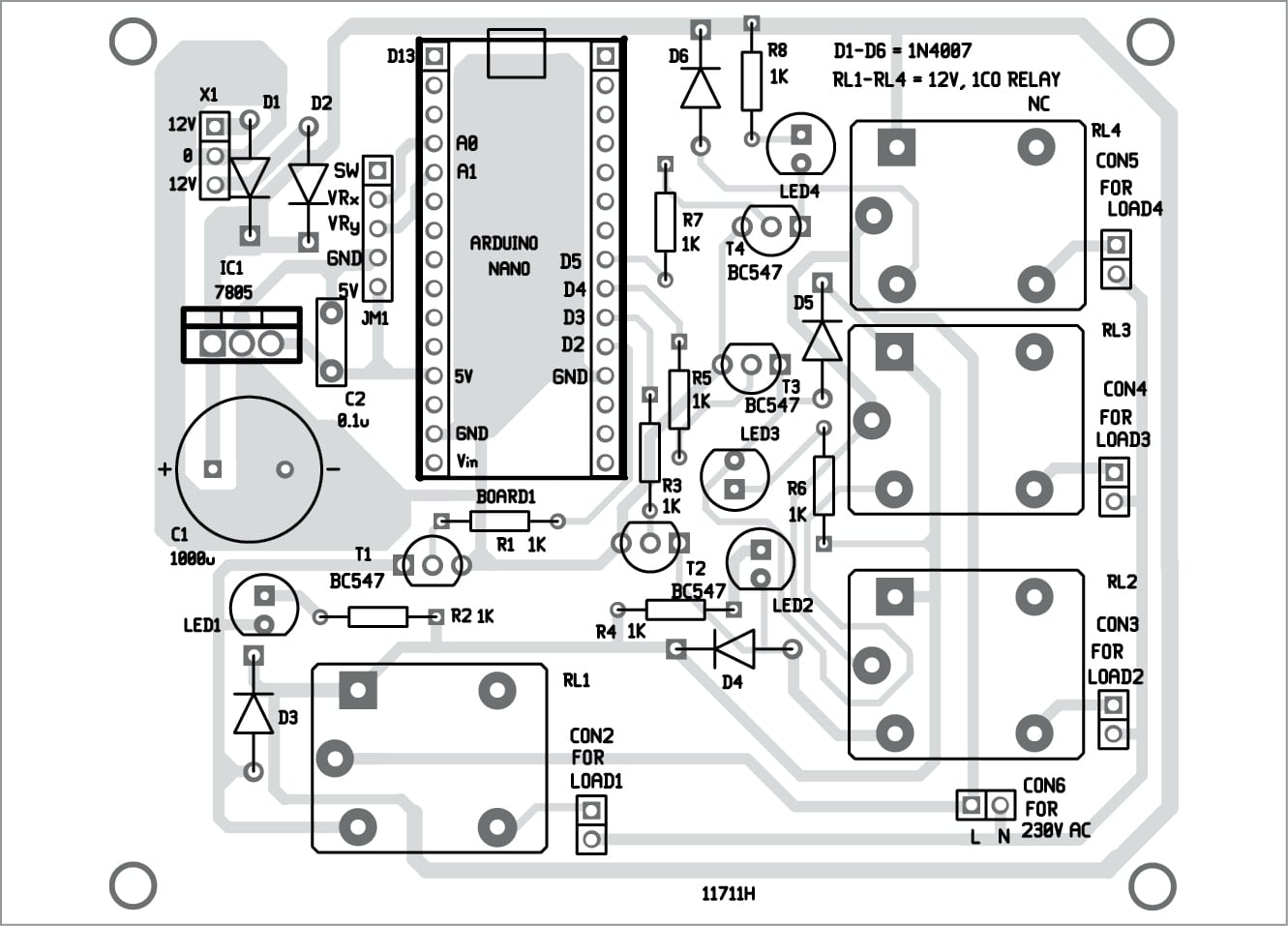

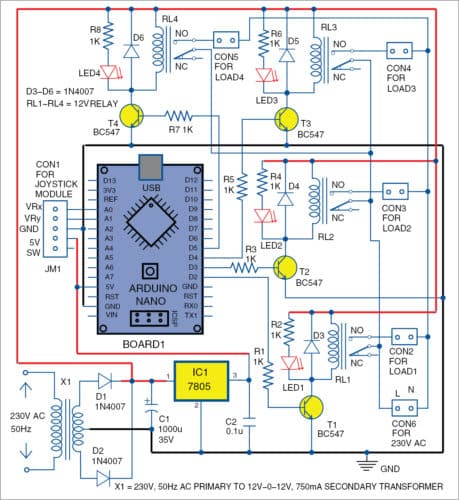

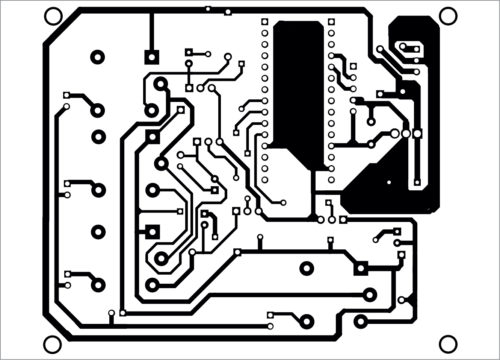

Joystick-Controlled Industrial Automation System | Full DIY Project

www.electronicsforu.comjoystick controlled automation pcb electronicsforu

www.electronicsforu.comjoystick controlled automation pcb electronicsforu

Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick-Controlled Arduino Robotic ARM -Arduino Mini Project

electrodsm.wordpress.com### Joystick-Controlled Arduino Robotic ARM -Arduino Mini Project

www.pantechsolutions.net### Joystick-Controlled Industrial Automation System – Electro DSM

www.pantechsolutions.net### Joystick-Controlled Industrial Automation System – Electro DSM

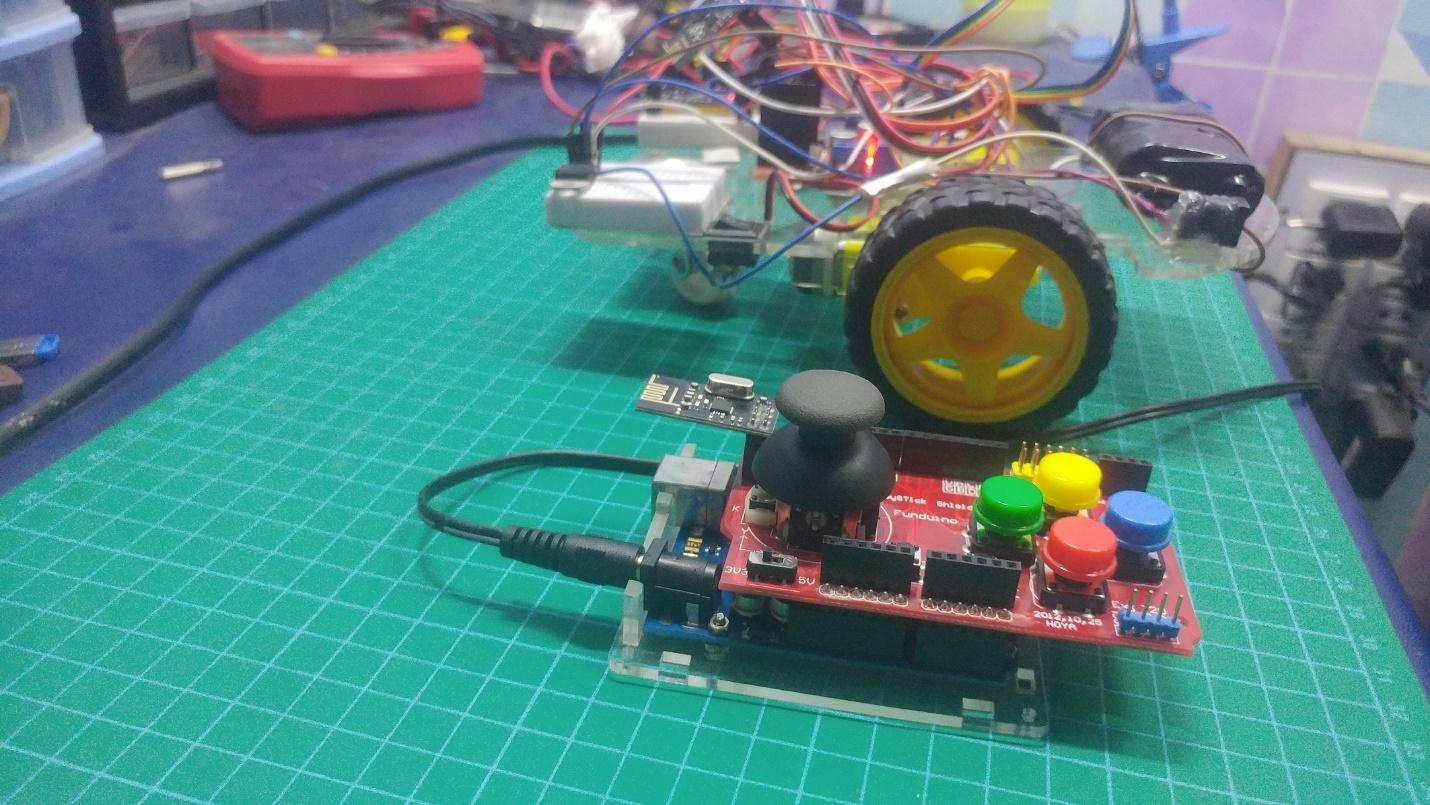

electrodsm.wordpress.com### Funduino (Arduino Joystick Shield) Controlled Robot | Arduino | Maker Pro

electrodsm.wordpress.com### Funduino (Arduino Joystick Shield) Controlled Robot | Arduino | Maker Pro

maker.proarduino joystick shield funduino maker pro projects

maker.proarduino joystick shield funduino maker pro projects

Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

www.electronicsforu.comjoystick controlled automation

www.electronicsforu.comjoystick controlled automation

Joystick-Controlled Industrial Automation System | Full DIY Project

www.electronicsforu.comjoystick matlab speech spectrogram controlled

www.electronicsforu.comjoystick matlab speech spectrogram controlled