Foam Hot Knife Cutter

In the realm of crafting and DIY projects, few tools are as versatile and transformative as the foam hot knife cutter. This innovative device employs heat to slice through various types of foam materials with remarkable precision. Yet, its significance transcends mere function. Understanding the multifaceted utility of the foam hot knife cutter unveils a cornucopia of opportunities for both amateur crafters and seasoned artisans alike.

The allure of the foam hot knife cutter lies not just in its prowess for cutting but also in the myriad creative applications it facilitates. This tool is particularly revered for its efficacy in manipulating materials like polystyrene, polyethylene, and polyurethane foams, which are common in a plethora of applications ranging from arts and crafts to industrial design. By utilizing a heated blade, the cutter enables users to achieve clean, smooth edges that would otherwise be challenging to attain through traditional cutting methods.

Moreover, the thermal cutting process is accompanied by a reduction in debris. Unlike conventional saws or knives, which tend to tear the material, the hot knife penetrates effortlessly, fusing the foam’s cellular structure and eliminating fraying. This feature not only enhances the aesthetic appeal of the finished product but also substantially decreases cleanup time, engendering a more efficient workspace.

In addition to cutting, the foam hot knife cutter is an exceptional tool for shaping and sculpting. It allows artisans to craft intricate designs and curves that are often essential in projects such as model making, prop fabrication, and even upscale artistic endeavors. The ability to manipulate foam into elaborate forms empowers creators to explore their artistry without facing the constraints imposed by more rigid materials. This is particularly advantageous in scenography, where designers may require detailed, lightweight components to create visually stunning environments.

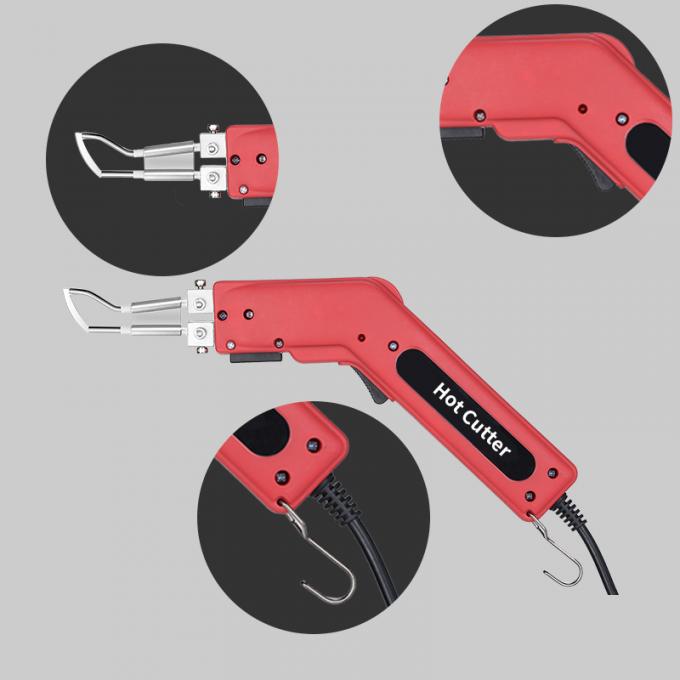

Another compelling aspect of foam hot knife cutters is their compatibility with a range of accessories, thereby broadening their functional repertoire. For instance, many models come equipped with interchangeable blades designed for specific tasks, such as beveling and contouring. This adaptability underscores the practicality of the tool, as crafters can customize their approach based on project requirements, thus enhancing their creative processes.

Nevertheless, a foam hot knife cutter is not without its challenges. Safety considerations are paramount; the heated blade can reach significant temperatures, necessitating the use of appropriate protective gear. Users should safeguard against thermal burns by employing gloves, goggles, and work surfaces that can withstand heat. Furthermore, adequate ventilation is crucial when cutting certain types of foam, as toxic fumes may be released. A well-ventilated workspace ensures a secure environment for crafting without health hazards.

As with any specialized tool, the choice of a quality foam hot knife cutter is essential. The market is replete with options, and discerning which model best aligns with one’s crafting needs can be daunting. Factors to consider include temperature settings, blade material, and the manufacturer’s reputation. Some models offer adjustable heat settings, allowing users to tailor the temperature for different foam types and thicknesses. A robust, ceramic-coated blade often provides longer-lasting heat retention and durability, translating into a more reliable cutting experience.

Furthermore, the incorporation of ergonomic designs enhances user comfort, especially for prolonged projects. Craftspeople may find tools with cushioned grips and a balanced weight distribution contribute to a more controlled and enjoyable crafting session. This attention to physical usability encourages creativity, allowing the creator to focus on the project rather than discomfort.

In contemporary crafting, sustainability is becoming increasingly prominent, prompting individuals to seek eco-friendly materials. Here, the foam hot knife cutter shines yet again, as it allows for the precise cutting and shaping of alternatives like biodegradable foams or recycled materials, thereby aligning with environmentally conscious practices. This nexus of creativity and sustainability is crucial in a world striving towards conscientious consumption and artistic expression.

As we delve deeper into the applications of the foam hot knife cutter, it becomes evident that this tool extends beyond simple craft projects. Artists in fields such as theater and film utilize hot knives to construct elaborate set designs that require both versatility and lightweight materials. Additionally, educators find value in this tool, employing it in classrooms to introduce students to the principles of design and engineering through hands-on projects.

To encapsulate the advantages of the foam hot knife cutter, it is a synthesis of functionality, innovation, and versatility. This tool possesses the capacity to elevate mundane crafting into an engaging and dynamic pursuit, pushing the boundaries of what can be created from foam. It caters to a diverse range of applications, satisfying the demands of artists, hobbyists, and professionals alike.

In conclusion, the foam hot knife cutter is more than just a tool; it is a bridge between imagination and reality, enabling users to transform fleeting ideas into tangible creations. As the crafting world continues to evolve, the role of this instrument will likely expand, fostering creativity and providing new avenues for artistic exploration. Whether it’s for a simple hobby or an ambitious project, the foam hot knife cutter remains an indispensable ally in the toolkit of any modern creator.

If you are looking for Choosing the Ideal Hot Knife Foam Cutter — Learn More you’ve visit to the right page. We have 10 Pictures about Choosing the Ideal Hot Knife Foam Cutter — Learn More like Electric DIY hot knife foam cutter - EPSTEC China EPS machine, Electric Knife Hot Knife Foam Cutter Foam sculpture hot knife cutter and also Choosing the Ideal Hot Knife Foam Cutter — Learn More. Here you go:

Choosing The Ideal Hot Knife Foam Cutter — Learn More

www.carolinaknife.com### KD-15-400 Hot Cutter Knife Heavy Duty Industry Electric Foam Cutter

www.carolinaknife.com### KD-15-400 Hot Cutter Knife Heavy Duty Industry Electric Foam Cutter

www.hot-knife.cncutter foam kd canty cn

www.hot-knife.cncutter foam kd canty cn

SC-190 Hot Knife Foam Heat Cutter Kit, Styrofoam Cutter - Coast

cameduae.comstyrofoam camed foam rods

cameduae.comstyrofoam camed foam rods

Buy Electric Hot Knife Cutter SEAAN Foam Cutter Tool 150W Electric Hot

www.desertcart.com.my### Electric DIY Hot Knife Foam Cutter - EPSTEC China EPS Machine

www.desertcart.com.my### Electric DIY Hot Knife Foam Cutter - EPSTEC China EPS Machine

www.epstec.com### Hot Wire Foam Cutter KD-60 - Buy Foam Cutter, EPS Foam, Hot Wire Foam

www.epstec.com### Hot Wire Foam Cutter KD-60 - Buy Foam Cutter, EPS Foam, Hot Wire Foam

www.hot-knife.cncutter kd canty knife

www.hot-knife.cncutter kd canty knife

Electric Knife Hot Knife Foam Cutter Foam Sculpture Hot Knife Cutter

www.desertcart.aecutter

www.desertcart.aecutter

Fabric Hot Knife Foam Cutter Professional Controllable Temperature Rope

www.hot-cutter.com### Buy DOMINOX Air Cooling Foam Cutter Hot Knife Craft Knife Kit

www.hot-cutter.com### Buy DOMINOX Air Cooling Foam Cutter Hot Knife Craft Knife Kit

www.desertcart.com.cy### Hot Knife EPS Foam Cutter(KD-5H) - CHANGZHOU CANTY ELECTRIC INDUSTRY CO

www.desertcart.com.cy### Hot Knife EPS Foam Cutter(KD-5H) - CHANGZHOU CANTY ELECTRIC INDUSTRY CO

www.ecplaza.netknife hot cutter foam eps canty kd 5h ecplaza

www.ecplaza.netknife hot cutter foam eps canty kd 5h ecplaza