Joystick Controlled Industrial Automation System

In the realm of industrial automation, where precision and efficiency are paramount, the introduction of joystick-controlled systems has revolutionized the way operators interact with machinery. Just as characters in blockbuster films—like Tony Stark with his high-tech Iron Man suit or the iconic Luke Skywalker wielding his lightsaber—effortlessly manipulate advanced technology, industrial controllers are harnessing joystick interfaces to simplify complex operations. This article explores how joystick-controlled industrial automation systems have become a game changer in various industries, enhancing productivity while reducing manual fatigue.

Imagine a factory bustling with activity. Robots meticulously assembling products, conveyor belts transferring goods with remarkable speed, and operators at the helm, steering monumental machinery with unparalleled ease. Enter the joystick, a device that transcends traditional controls, allowing for intuitive manipulation akin to gaming consoles that have captured the hearts of millions. The ergonomic design and fluid movement of a joystick enable operators to navigate intricate functions with a flick of the wrist, allowing for unparalleled precision in the operation of heavy machinery.

The transition from outdated manual controls to a joystick-based interface has multiple benefits. First, it offers enhanced control over equipment. In environments involving cranes, robotic arms, or even complex CNC machines, the ability to maneuver with a joystick allows for remarkable agility and responsiveness. Operators can make real-time adjustments, minimizing errors and increasing efficiency. Moreover, the incorporation of joystick controls often introduces advanced features such as programmable buttons, providing an additional layer of customization to optimize workflow.

Furthermore, safety is significantly bolstered through the implementation of joystick-controlled systems. Conventional controls can sometimes lead to fatigue and inattention, leaving room for oversight. Conversely, joystick interfaces facilitate a more engaging operational experience, keeping the operator’s focus sharp. The tactile feedback received from the joystick offers intuitive spatial awareness, thus decreasing the likelihood of accidents involving heavy machinery—a vital consideration in high-stakes environments like shipyards or assembly lines.

One might wonder about the versatility of joystick-controlled systems. Their applications can be found across diverse fields, from manufacturing to healthcare. In the automotive industry, for instance, robotics facilitated by joystick operation can streamline assembly processes, reducing both time and labor costs significantly. Likewise, in the agricultural sector, joystick-controlled tractors can execute precision tasks, steering through crops with the kind of accuracy that empowers farmers to maximize yield while conserving resources.

Healthcare has also embraced joystick technologies, particularly in surgical settings. Surgeons now use joystick-operated robotic systems, allowing for minutiae movements during delicate procedures. Think of it like Yoda meticulously guiding Luke through his Jedi training—hand over hand movements translated into robotic precision. These systems not only enhance the capabilities of healthcare professionals but also revolutionize patient outcomes, paving the way for minimally invasive surgeries and quicker recoveries.

Notably, the burgeoning field of virtual reality (VR) and augmented reality (AR) has capitalized on joystick-controlled systems as well. Training simulations for operators in hazardous environments, utilizing VR platforms, often integrate joystick navigation. Operators can undergo comprehensive training in a controlled setting, honing their skills before engaging with actual machinery. This thoughtful application serves to lessen potential liabilities for organizations, equipping personnel with the confidence and competence required in demanding work environments.

In terms of installation and operation, the technological landscape has evolved to make joystick integration seamless. Many industrial machinery manufacturers now offer optional joystick interfaces as part of their control systems. This flexibility enables companies to modernize their operations without extensive overhauls of existing infrastructure. Moreover, the modularity of joystick controllers often allows for easy upgrades, as technological advancements continue to emerge at a rapid pace. A hallmark of contemporary industrial automation is its adaptability, responding to the ever-changing demands of the marketplace.

As we look to the future, the rise of IoT (Internet of Things) technology will further amplify the potential of joystick-controlled industrial automation systems. Imagine a network of machines communicating with each other, with operators using joysticks to initiate coordinated actions across an entire plant. This interconnectedness could lead to synergies that were once thought impossible, pushing the boundaries of what we consider efficient industrial operation. Like the crew aboard the Starship Enterprise, navigating the universe in perfect harmony, factories of the future might find themselves fully integrated, with joystick interfaces serving as the command console.

In closing, joystick-controlled industrial automation systems represent a synthesis of technology and human ingenuity. As operators harness the power of these intuitive devices, industries are reshaping efficiency standards. Much like your favorite characters in epic narratives whose mastery over technology leads to extraordinary feats, the incorporation of joystick technology in industrial settings empowers personnel to reach new heights in productivity and safety. As the wheels of automation continue to turn, one thing remains certain: the joystick will remain at the forefront, steering us toward a future brimming with potential.

If you are searching about industrial joystick controller you’ve came to the right page. We have 10 Images about industrial joystick controller like Joystick-Controlled Industrial Automation System – Electro DSM, Joystick-Controlled Industrial Automation System – Electro DSM and also Joystick-Controlled Industrial Automation System | Full DIY Project. Read more:

Industrial Joystick Controller

www.knob-joystick.com### Joystick-Controlled Industrial Automation System – Electro DSM

www.knob-joystick.com### Joystick-Controlled Industrial Automation System – Electro DSM

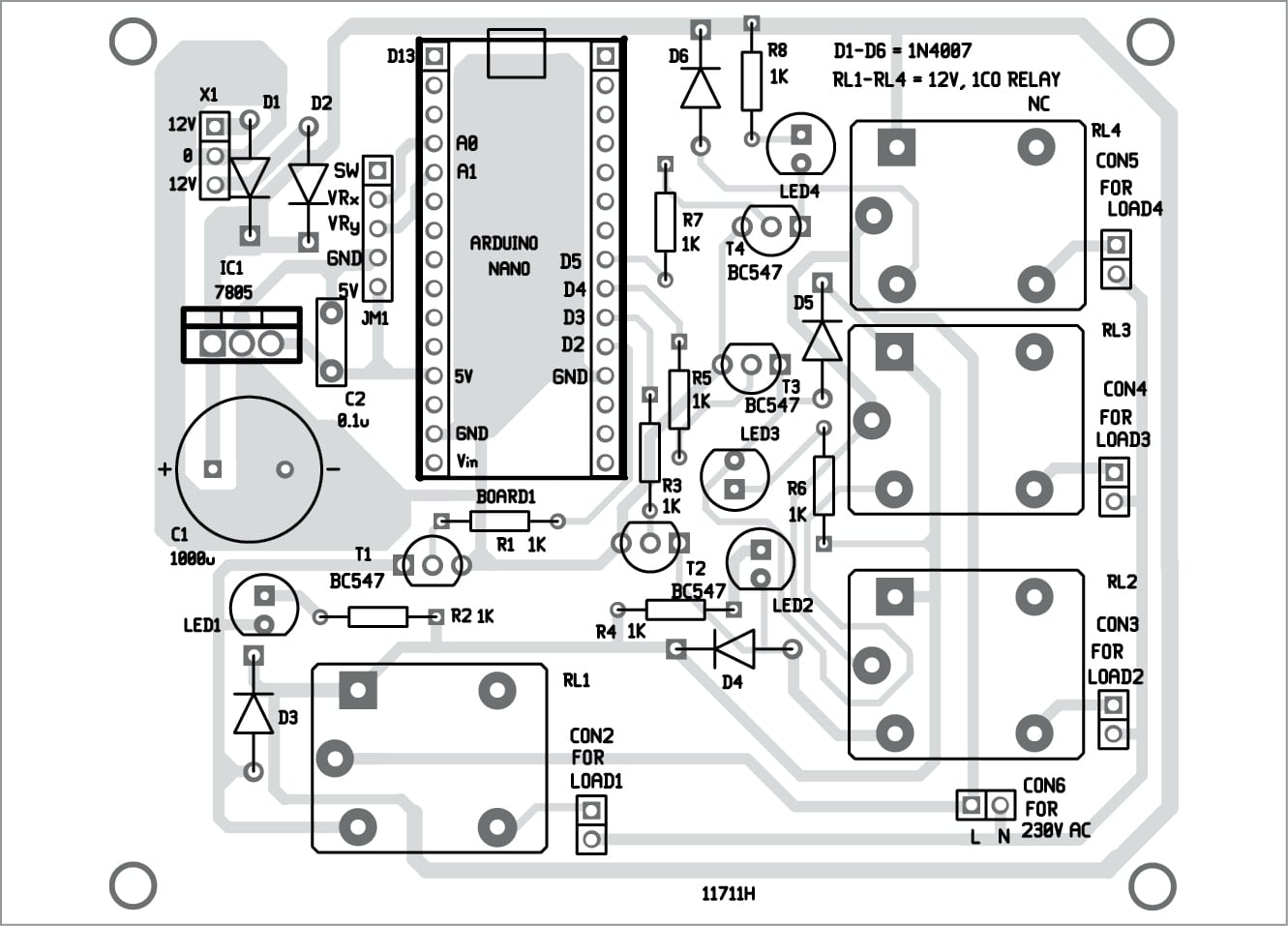

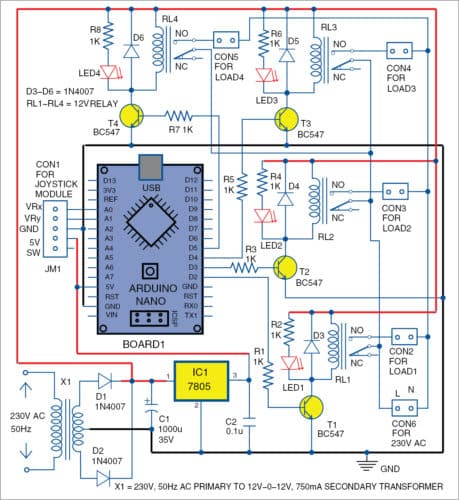

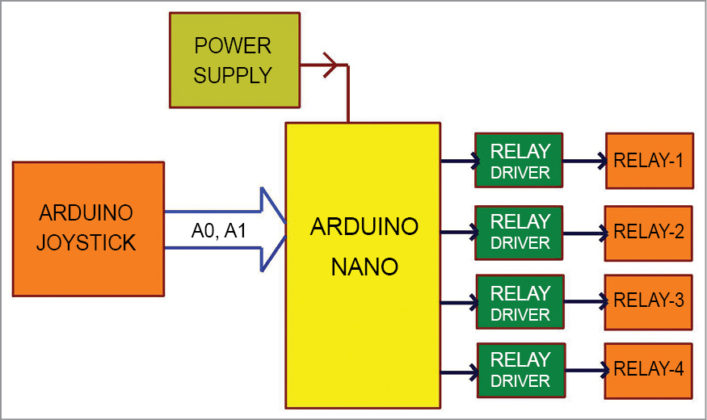

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

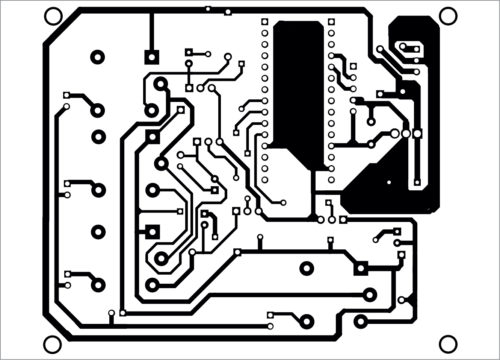

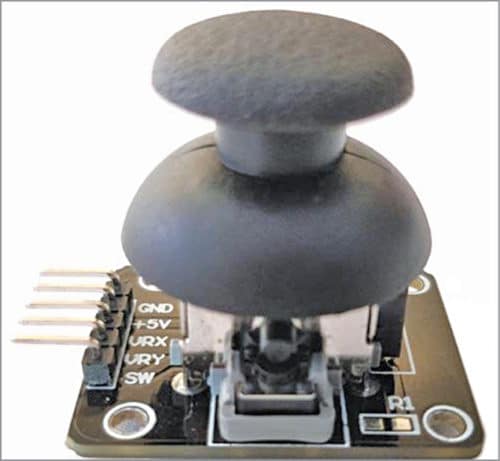

www.electronicsforu.comjoystick controlled automation pcb electronicsforu

www.electronicsforu.comjoystick controlled automation pcb electronicsforu

Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick Controllers

electrodsm.wordpress.com### Joystick Controllers

www.knob-joystick.com### Joystick-Controlled Industrial Automation System – Electro DSM

www.knob-joystick.com### Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System – Electro DSM

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

electrodsm.wordpress.com### Joystick-Controlled Industrial Automation System | Full DIY Project

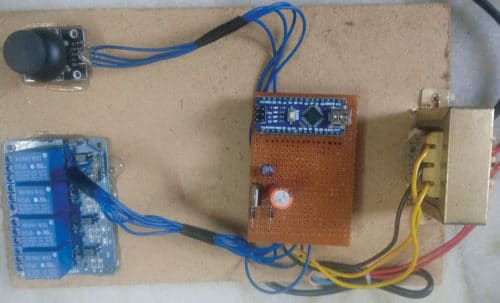

www.electronicsforu.comjoystick controlled automation

www.electronicsforu.comjoystick controlled automation

Joystick-Controlled Industrial Automation System | Full DIY Project

www.electronicsforu.comjoystick matlab speech spectrogram controlled

www.electronicsforu.comjoystick matlab speech spectrogram controlled

China Industrial Joystick Controller Manufacturers, Suppliers - Cheap

www.joystick-knob.comjoystick controller

www.joystick-knob.comjoystick controller