Quick Connect Air Fittings Types

In the realm of pneumatic systems, quick connect air fittings play a pivotal role in enhancing efficiency and flexibility. These fittings facilitate swift and secure connections, thereby streamlining the entire process of component integration in various machinery. From automotive applications to industrial assembly lines, understanding the types of quick connect air fittings is paramount for anyone operating within these sectors. This article will traverse through the diverse categories of these fittings, offering nuances in functionality, design, and application.

One of the most fundamental aspects of quick connect air fittings is their ability to provide a seamless transition between air hoses and tools, a critical feature that minimizes downtime and maximizes productivity. But before delving into the specific types, it is essential to grasp the terminology associated with these fittings. Various terms such as “male,” “female,” “threaded,” and “barbed” often arise, each denoting specific attributes that ultimately affect the fitting’s performance and compatibility. Thus, armed with the requisite vocabulary, one can better navigate the vast array of options available.

1. Industrial Quick Connects

Industrial quick connects are robust connecters designed for heavy-duty applications. These fittings provide a reliable connection for higher pressure applications in factories and manufacturing plants. Typically made from durable materials like brass or stainless steel, industrial quick connects can withstand harsh conditions. They often feature a locking mechanism that prevents accidental disconnection, ensuring safety and efficiency in fast-paced environments. Additionally, these fittings come in various sizes, accommodating a range of hose diameters.

2. Automotive Quick Connect Fittings

In the automotive industry, quick connect fittings are essential for fluid transfer systems such as transmission lines, coolant hoses, and air conditioning systems. Automotive quick connects often have a self-locking mechanism, which provides a secure fit while also allowing ease of disassembly for maintenance and repair. Some of these fittings are designed with unique shapes to facilitate specific alignment or routing of hoses, ensuring optimal performance under the hood of vehicles. Moreover, compatibility with various fluid types, including oil and antifreeze, is a vital characteristic of these fittings.

3. Pneumatic Quick Connect Fittings

Pneumatic quick connect fittings, as indicated, are specifically designed for air-powered tools and machinery. Utilizing a push-to-connect mechanism, these fittings allow users to easily attach and detach hoses, making them ideal for applications that require frequent changes of tools or equipment. Pneumatic fittings come in several styles, including straight, elbow, and tee configurations, each catering to different spatial constraints and operational requirements. Furthermore, the capacity to endure fluctuating pressures without compromising integrity is a hallmark of pneumatic fittings.

4. Barbed Quick Connect Fittings

The barbed quick connect fitting is characterized by its protruding ridges, which promote a secure grip onto the hose. These fittings are particularly favored in low-pressure applications or scenarios where flexibility and ease of assembly are paramount. The design allows for minimal tool use during installation while ensuring a snug fit to prevent leaks. Barbed fittings are often made of plastic or soft metals, making them lightweight and easy to handle. Their versatility is evidenced by their application across gardening, aquaculture, and even home plumbing systems.

5. Threaded Quick Connects

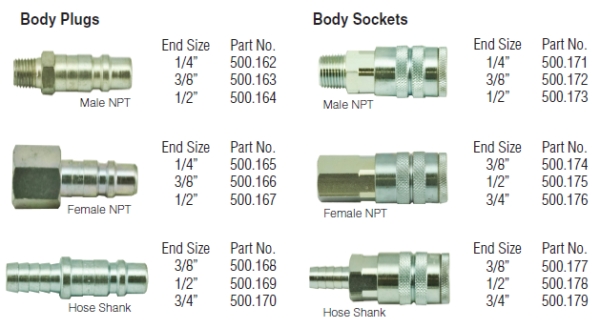

Threaded quick connect fittings employ a screw-type mechanism that enables a strong, leak-proof connection between components. This type is extensively used in systems where the fittings must withstand considerable mechanical stress. Threaded fittings often come with standard sizes such as NPT (National Pipe Thread) or BSP (British Standard Pipe), allowing for greater compatibility across various systems and jurisdictions. They may require tools for installation and removal, which can be a disadvantage in settings that prioritize rapid assembly and disassembly. Nevertheless, their reliability in high-stress environments often outweighs this potential drawback.

6. Push-to-Connect Fittings

Push-to-connect fittings, often referred to as instant fittings, have revolutionized the industry by simplifying the connection process. With a straightforward push mechanism, users can create a secure connection without the need for additional tools or excessive force. These fittings often utilize O-rings or seals to prevent leakage, making them especially suitable for automotive and pneumatic applications. Push-to-connect fittings not only save time during assembly but also contribute to a cleaner system, as they minimize the chance of atmospheric contaminants entering the line.

7. Specialty Fittings

Lastly, specialty quick connect fittings exist to address unique challenges and accommodate specific requirements across different applications. These can range from fittings designed for high-temperature application to those made for corrosive environments. Examples include polyethylene fittings often used in chemical processing or high-temperature silicone fittings used in automotive exhaust systems. The design and material selection for these specialty fittings are essential in ensuring long-lasting performance and reliability.

In summation, quick connect air fittings are integral components that facilitate myriad applications across various industries. Understanding the differences among the types—including industrial, automotive, pneumatic, barbed, threaded, push-to-connect, and specialty fittings—enables professionals to make informed decisions based on their specific requirements. Such knowledge not only enhances operational efficiency but also safeguards against common issues such as leaks and unintentional disconnections. Ultimately, the right quick connect fitting can make a substantial difference in the performance and longevity of pneumatic systems.

If you are searching about Quick Connect Air Fittings Types - nolyutesa you’ve came to the right place. We have 10 Pics about Quick Connect Air Fittings Types - nolyutesa like quick connect air fittings types - Ela Rutledge, quick connect air fittings types - Ela Rutledge and also quick connect air fittings types - Shanika Purnell. Here you go:

Quick Connect Air Fittings Types - Nolyutesa

nolyutesa.blogspot.comhose valve inflator

nolyutesa.blogspot.comhose valve inflator

Quick Connect Air Fittings Types - Ela Rutledge

worship247wknd.blogspot.com### ½” Hanson Type Industrial Quick-Connect Fittings - Desco Manufacturing

worship247wknd.blogspot.com### ½” Hanson Type Industrial Quick-Connect Fittings - Desco Manufacturing

www.descomfg.comquick connect fittings industrial type hanson air

www.descomfg.comquick connect fittings industrial type hanson air

Quick Connect Air Fittings Types - Ela Rutledge

worship247wknd.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

worship247wknd.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com### Brass Quick Connect Air Fittings Air Line Quick Connect Fittings CE

shanikapurnell.blogspot.com### Brass Quick Connect Air Fittings Air Line Quick Connect Fittings CE

www.pneumatic-equipments.comfittings air brass line ce certification connect quick details

www.pneumatic-equipments.comfittings air brass line ce certification connect quick details

Quick Connect Air Fittings Types - Ela Rutledge

worship247wknd.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

worship247wknd.blogspot.com### Quick Connect Air Fittings Types - Shanika Purnell

shanikapurnell.blogspot.com

shanikapurnell.blogspot.com